|

Advantages

- Bright surface

- No decarburization

- No oxidation

- Minimized distortion

- Reproducibility

- Vacuum high

temperature brazing

- Economical

|

|

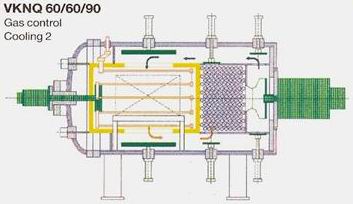

| TECHNICAL

DATA VKNQ |

|

Working Space

600x600x900 mm

- Charge Weight

500 Kgs max

- Rated Temp.

1,300 oC max

- Temp. Uniformity

< + - 5 oK

- Quenching N2

Gas 6~10 bars

- Vacuum 10 -2

~10 -5 mbars

Manufactured by ALD (Germany)

|

|

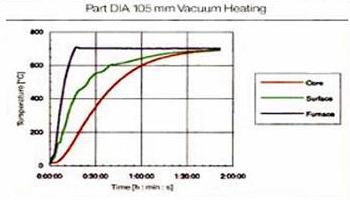

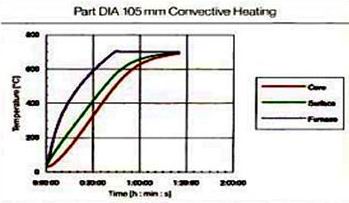

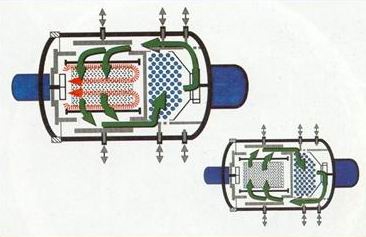

| PROCESS

CONVECTIVE HEATING |

- Heat transfer

takes place by radiation only in vacuum, which is

ineffective at lower than 500 oC and develop large

temperature difference between surface and core of

work piece. Such temperature difference should make

thermal stress, which might cause some distortion

of work piece.

- By adding N2

gas of 2 bars for heat convector, homogeneous and

rapid heating can be achieved.

|

|

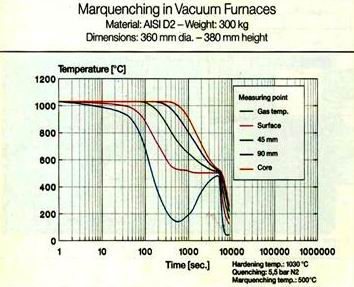

| PROCESS

MARQUENCHING |

- In case of

parts with large sections and complicated shapes,

rapid quenching may lead to crack and/or serious distortion

on work piece.

- By programmed

controlling quenching above Ms point of material by

using two thermocouples installed on surface and core

of a dummy with charge, minimized distortion can be

achieved.

|

|

| PROCESS

Reversible Direction |

|

QUENCHING

- In quenching

process, it is said that steel has to be quenched

as fast and slowly as possible.

- The former

is for enough cooling speed to obtain ideal micro

structure, the latter is for prevent cracking and

severe distortion of work.

- Our furnace

makes both available by high pressure gas quenching,

by programmable reversible cooling and by Marquenching

|

|

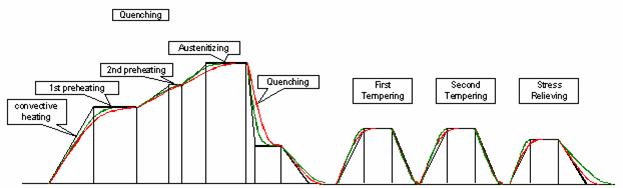

| Concept

Heat Treatment of HIGH ALLOYED TOOL STEELS |

- Hardening of

high alloyed tool steels have to be carried out in

way of vacuum process, in order to prevent any oxidation

and decarburization.

- In our vacuum

process, a dummy block of which diameter is equivalent

to the control section of work piece to be hardened.

Two thermocouples installed at both core and surface

of the dummy can manage the temperature control of

work piece at both surface and core throughout its

hardening procedure. By this way we are able to ;

-

- manage any

thermal stress which may arise while heating work

piece up and minimize any distortion.

- prevent insufficient

austenitizing of core and over solution of carbides

through austenitizing by controling austenitizing

by core temperature.

- apply marquenching

procedure in order to prevent cracking and minimize

any distortion by both thermal and transforming stress

in case of complicated shape work piece.

Three high temperature temperings are to done as general

rule. The first temper is for decomposing retained

austenite which is unavoidable in high carbon and

high-alloyed tool steels. By the second tempering

we control hardness required. The third tempering

is stress relieving to prevent any cracking and deforming

through the subsequent process.

|

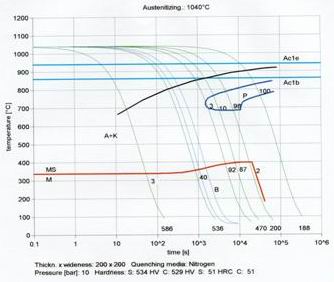

| Hot

work Alloyed Tool Steel |

- Though hot

work alloyed tool steels have good hardenability and

be enable to harden by gas quenching in vacuum process,

as the size of mold become larger recently, early

cracking problem has reported and quenching speed

has been to be discussed.

- According to

CCT curve left, bainite transforms in earlier stage

than pearlite and it will accompany some amount of

retained austenite in matrix. Carbides precipitated

on boundary of austenite by tempering are considered

the cause of early cracking.

- In our vacuum

process, quenching nitrogen up to 10 bars can be used

and can increase effective quenching speed by alternative

direction quench program. Thus we will try to reduce

bainite, intending long life mold making.

- We also recommend

the late bainite transform type steels recently announced.

|

|

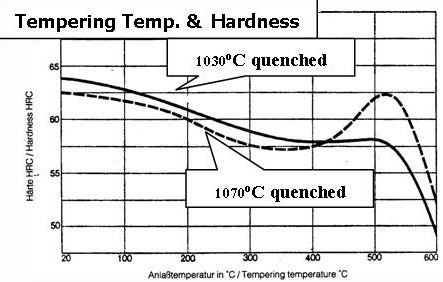

| Cold

Work Alloyed Tool Steels |

- Retained austenite

may not be avoided by quenching this kind of steels

because of high carbon and alloyed elements.

- Retained austenite

often causes cracking or distortion of work piece

in subsequent wire cut or grinding, subzero treatment

or 2 times high temperature tempering are recommendable.

- By high temperature

tempering, hardness specified shall be HRC55~58. When

HRC60 is needed, austenitizing temperature must be

applied 1070oC that is higher than usual one of 1030oC,

in order to harden by second hardening. This process

is not recommendable because it increases retained

austenite.

- Further stress

relieving is to be carried out for any subsequent

machining process

|

|

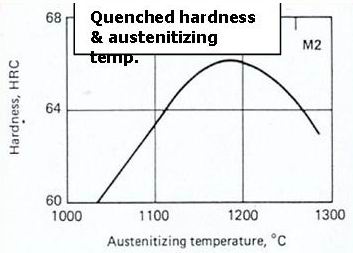

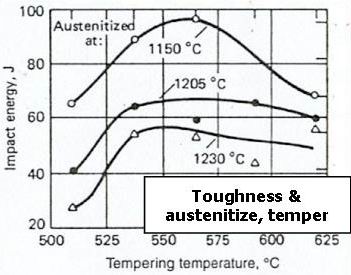

| High

Speed Steels |

- High speed steel,

as it shown in its name, has developed for cutting

tools which can keep high hardness even if temperature

of tools come up into red condition by high speed

cutting. For this purpose, austenitizing must be carried

out at 1200oC for high hardness.

- Tempering shall

be carried out more than 3 times, as this steel has

a lot of retained austenite after quenched.

- Thin cutting

tools can be straightened taking an advantage of existing

retained austenite after quenched while warm.

- High speed steel

may be used in room temperature and instead high toughness

is required. In this case, austenitizing shall be

lower than usual. The pocess for high toughness is

called as under hardening.

|

|

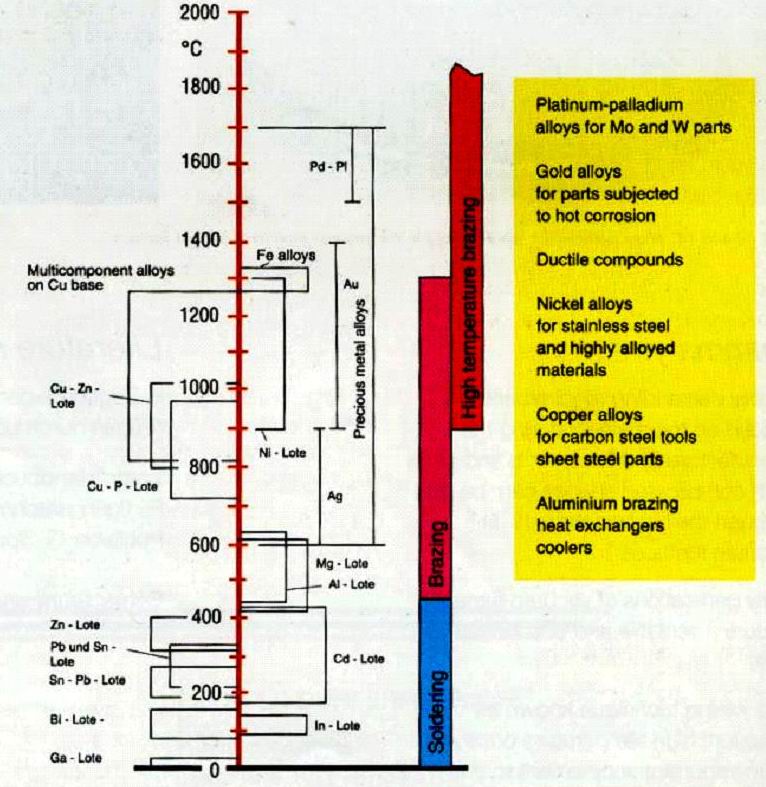

| Vacuum

high temperatureAdvantageous BRAZING |

- Oxide film

on base metal bursts and be removed by vacuum and

metal wall gets wet with alloy which enables good

brazing.

- By heating

the work piece to high temperature in vacuum, enough

diffusion is available between metals and good bonding

with no inclusion nor gas hole can be attained.

- Very narrow

brazing gaps of less than 0.05mm makes bonding metals

with high strength and good accuracy.

|

|

|

|

Top

|