| |

|

|

| Tufftride

QP, QPQ |

|

|

|

Tufftride

is a salt bath nitriding process by Dufferit in Germany,

and has been in use in a wide range of industries.

- The process

is carried out in a subcritical (510~580oC) bath,

where nitrogen and small amount of carbon are diffused

into the surface of component and conform e-iron compound

on surface layer of component.

- The hardness

of compound layer, ranging from 400 to 1200 HV depending

on the base material used, is responsible for fatigue,

wear and galling resistance

|

| Examples

of Application |

- Hot work tools

: Forging, extrusion, die casting mould

- Cold work tools

- High speed

steel tools

- Crank shaft,

Cam shaft

- Cylinder liner,

block & head

- Gears

- Diesel engine

valve

- Plastic injection

screw & barrel

- Food processing

equipments & tools

|

|

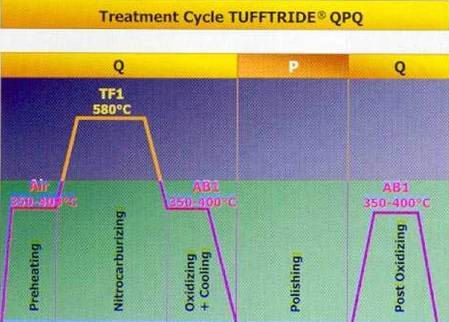

- QP is the liquid

soft nitriding process applicable for any kind kind

of steel.

- Process is very

quick compared with the other nitriding process in

case of both small or large lot production.

- High surface

hardness obtained by theis process, makes tool life

longer.

- QPQ is an oxidizing

cooling process by using special salt of AB1, after

QP process is done.

- By applying

QPQ treatment, corrosion resistance will be much improved

along with wear resistance

|

|

|

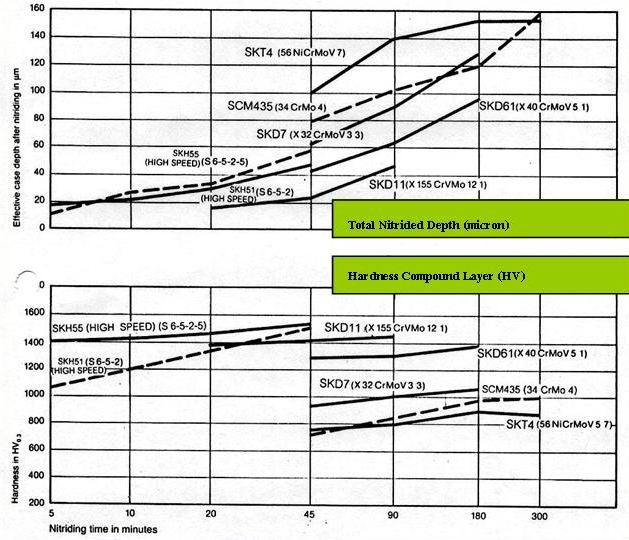

| Hardness

and Case depth |

|

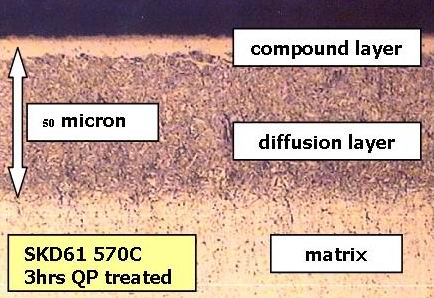

Nitrided layers

by Tufftride process consists of white layer (compound

layer) and diffusion layer

- Characters

of surface of product is mainly affected by white

layer.

- Surface hardness

and thickness of both layers depend on the material

used and on nitriding duration.

- Figures right

are quoted from Bohler book.

|

|

| Our

Facilities |

Ø 500

x 750 mm

Ø 710 x 1500 mm

Ø 1000 x 1500 mm

- QPQ AB1 SALT

BATH

50x1000x1400mm

Ø 1000

x 1500 mm

|

|

| Corrosion

Resistance by QPQ |

|

By

applying Tufftride QPQ process, corrosion resistance

is dramatically improved.

To

determine the corrosion resistance of sample and component,

a salt spray test (German Standard DIN 50021) and a

total immersion test (DIN 50905) are often carried out.

The

under figure shows the result of a salt spray test by

a 5% salt solution at 35o C on both hard chrome plated

piston rod and Tufftride QPQ treated carbon steel bars.

After 40 hours, the first corrosion spots occurred on

the chrome plated piston rods. After 180 hours, the

chrome plated rods showed very heavy corrosive attack

over a large area. The QPQ treated rods, however, showed

no sign of corrosion.

|

|

|

|

Top

|

|

|

|