| |

|

|

|

FLAME

HARDENING

|

|

|

|

- Flame hardening

is one of surface hardening process, in which a thin

surface shell of steel or cast iron is heated rapidly

to Austenite by high temperature flame of mix gas

of propane and oxygen, then quickly be quenched to

get high hardness.

- The process

has advantages to improve abrasion resistance and

fatigue limit by compressive residual stress created

by surface hardening as same as induction hardening.

- The process

has no limit of part size and/or weight, and is suitable

and economical for small scale production. The cost

for making induction coil can be neglected.

|

|

- Flame for hardening

shall be neutral. By mix ratio of propane and oxygen

of 1.4 must be used for the highest temperature of

2,930oC obtainable.

- Flame hardening

is applicable on any heattreatable steel and cast

iron.

- The higher austenitizing

temperature by 20~30oC is suitable.

- The preheating

is recommendable in order to avoid rapid heating and

cooling on such work piece as of intricate shape or

of gray cast iron which has apprehension of cracking.

- By preheating

the hardened depth can be deeper and also cracking

season cracking can be prevented by self tempering

effect.

- Hardness obtainable

by this process on cast iron depend on its amount

of pearlite in matrix. Pre-normalizing for increasing

matrix pearlite is recommendable for the purpose.

|

|

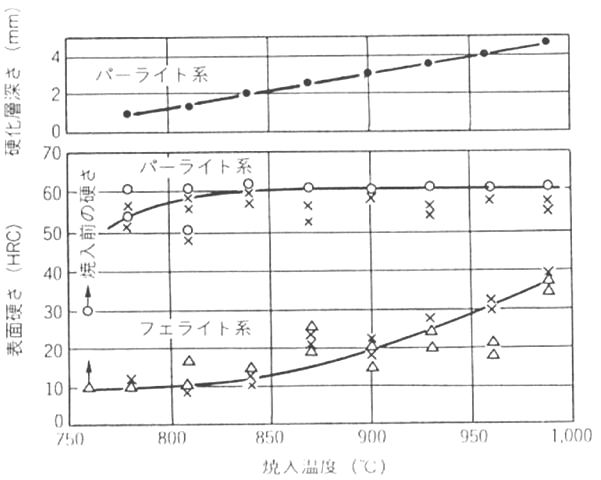

Effects

of matrix of FCD on flame hardened hardness and depth.

|

|

Response

of steel and cast to flame hardening (HRC)

|

|

Material

|

JIS

Symbol

|

Air

Cool

|

Oil

Cool

|

Water

Cool

|

|

SC

|

S20C,

S35C

|

-

|

-

|

33

~ 50

|

|

S38C,

S50C

|

-

|

52

~ 58

|

55

~ 60

|

|

S53C,

S58C

|

50

~ 60

|

58

~ 62

|

60

~ 63

|

|

SM

|

SCM

435

|

-

|

50

~ 55

|

50

~ 60

|

|

SCM

440

|

52

~ 56

|

52

~ 56

|

55

~60

|

|

SK-

|

SK

3, 4, 5, 6

|

52

~ 56

|

58

~ 62

|

62

~ 65

|

|

SUJ

|

SUJ

2

|

55

~ 56

|

55

~ 60

|

62

~ 64

|

|

FC

|

FC

300

|

-

|

43

~ 48

|

43

~ 48

|

|

FC

350

|

-

|

48

~ 52

|

48

~ 52

|

|

FCD

|

FCD

600

|

-

|

-

|

35

~ 45

|

|

FCD

700

|

-

|

52

~ 56

|

55

~ 60

|

|

|

|

|