| |

|

|

|

Bright

Hardening by Salt Bath

|

|

|

|

- Molten neutral

salt, Durferrit GS540/R2 by Degussa, covers the works

throughout heating works up and protects against decarburization

and scaling.

- Taking out the

works out of salt, thin film of salt is covering surface

of work pieces, pre-venting decarburization and scaling.

The film is easily pealed out in quenching media not

disturbing rapid cooling.

- As the heat

mass of the salt bath is huge, work pieces can be

heated and equalized 3 times as quick as other furnace,

and suitable for both small and mass production.

- The salt bath

is daily quality controlled by deslugging and checking

decarburization using some high carbon steel wire.

|

|

- Through quenching,

both thermal and transformation stresses arise by

temperature difference between surface and core of

complicated work piece. Those stresses might cause

crack or distortion of work piece.

|

|

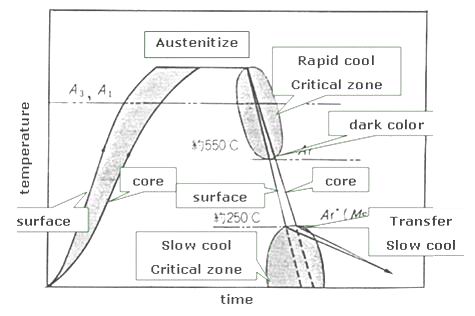

- In order to

prevent these ploblems, the work piece has to stop

cooling at just above the transformation start temperature

(MS), and then slow cooled. This process is called

as "time quenching".

|

|

|

Explanation

of time quenching

|

|

Austempering

|

Astempering is the special hardening process by

which the work pieces are quenched into

hot salt

bath and hold for hours to transform(isothermal

transform) in order to conform Bainite structure.

The Bainite structure has excellent high ductility

and toughness compares with those of tempered

Martensite by conventional quenching and tempering.

The table 1 below show an example of mechanical properties obtained by three different process. This

process is advantageous for minimizing deformation

and dimentional changes by hardening.

|

|

Table 1.

Mechanical properties by 3 different hardening process

|

|

|

|

|

|

The

relationship between hardness and austempering temperature

in case of SK5.

|

|

|

|

|

|