- Surface layer

of work-piece only can be heated by electro-magnetic

induction.

- High surface

hardness, wear resistance and high fatigue limit can

be obtained

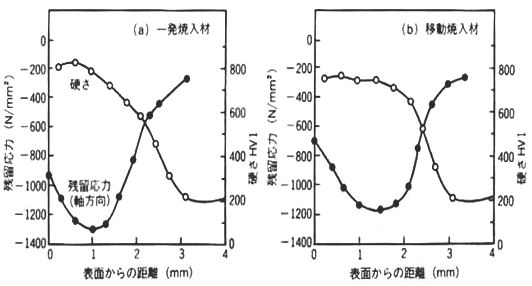

- Compressive

residual stress generated by induction hardening brings

superior fatigue limit.

- Process following

heat-treatment can be omitted because of little decarburization

or scaling of work piece.

- Quick and economical

for small lot production is available.

|

|

|

Quenching

spline part of shaft

|

| Facilities

INDUCTION HARDENING |

|

|

MADE

BY TOCCO(USA)

10KHz 150KW

&O slash;300x2,000 Max

CASE DEPTH 1~5 mm. |

MADE

BY DENSHIKAGAKU (JAPAN

200KHz 40KW

Ø 50x600 Max

CASE DEPTH 0.4 ~ 2.5 mm. |

| HARDNESS

& RESIDUAL STRESS |

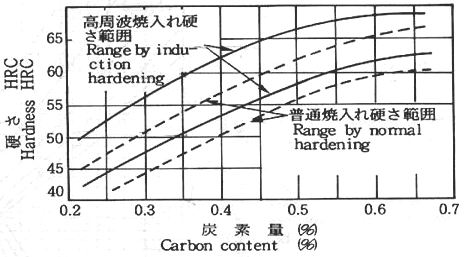

- Quenching hardness

depends on carbon content of material not on hardenability

of it.

- Hardness obtained

by induction hardening is higher than it by ordinary

quenching, because of compressive residual stress

generated by the process.

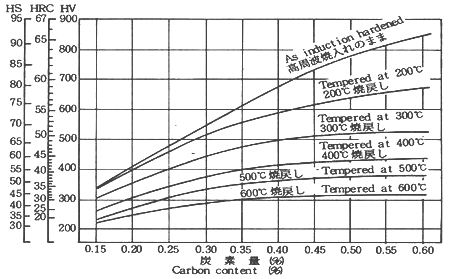

- While maintaining

hardness and residual stress, tempering is to be carried

out in order to prevent deforming, grinding crack

and to improve toughness.

|

|

|

Carbon

content & quenching hardness

|

|

|

|

Distribution

of hardness & residual stress

|

Carbon

content & tempered hardness

|

|

|

| INDUCTION

HARDENED DEPTH |

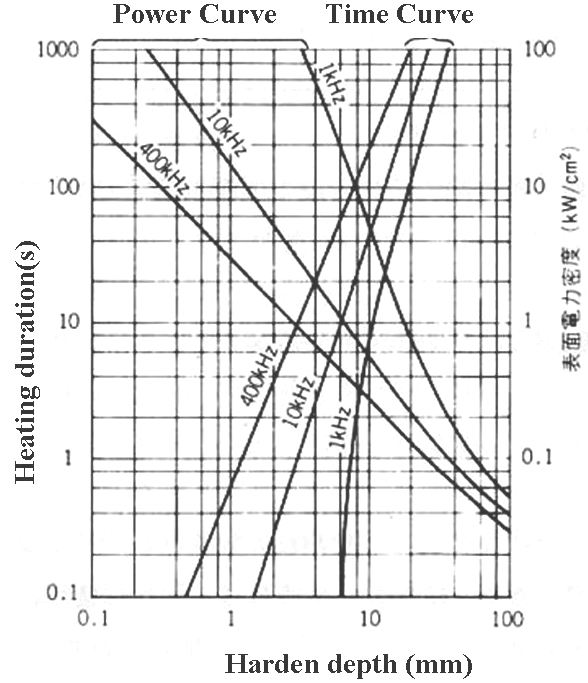

- For controlling

induction hardening, as it is difficult to measure

Austenitizing temperature directly, frequency(penetrate

depth), power density, ampere and voltage, heating

duration are used instead.

- The lower frequency

is applied, the deeper harden depth is obtained.

- There are two

kinds of heating up, those are one shot heating and

progressive heating.

|

|

| Relationship

between hardened depth and heating duration, power density

and frequency |

|

|

Top

|