| |

|

|

|

TD PROCESS VC hard

coating

|

|

|

|

Extremely high Vanadium carbile can be

applied on steel

substrate by TD PROCESS. The layer

improves resistance

against wear, scuffing, oxidation ,corrosion and etc.

Of steel products. Since the

process was invented by

Toyota Central Research and Developement Laboratories,

it has been used

for long period in worldwide

automobile industrie and other many field of industries.

|

|

The substrate

material be immerged into a high

temperature salt bath containing vanadium.

The

vanadium in sult

is to form VC (vanadium

carbile)

with carbon in substrate steel

which is diffused to the

surface of work.The principle of this process is

followed

by hardening and tempering

in order to attain the

mechanical properties required for substrate

material.

This process can be applied on

any substrate steel containing

carbon of 0.3%

and more. In case of

substrate of less than 0.3% carbon ,

precarburizing is recommended. |

|

|

|

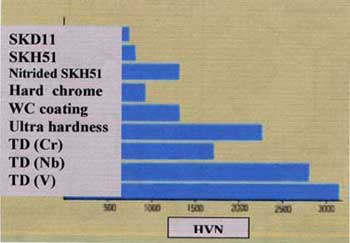

Hardness obtainable by this process will be

3000 Vickers Hardness , which is , needless

to say,

harder

than any kind of nitrided tool steel,

high speed

steel.

It is harder than tunsten carbile coating, hard

chrome

plating and ultra hardness steels. As the VC

layer of

this process ismadeby

diffusion of carbon

from

substrate ,the layer adhered to the substrate work

pieces and never peel out even used in hard

working.

The VC layer also shows excellent

anti corrosion characteristics. |

|

|

|

|

|

|

Sequence

of TD Process

|

|

|

|

|

|

|

|

|

|

|

TD.WORKING.ZONE

|

|

|

|

|

|

|

|

|

|

Top

|

|

|

|

|