| |

|

|

|

What’s

CARBURIZING ?

|

|

|

|

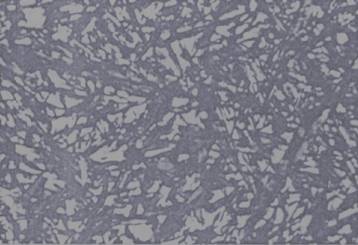

- Carburizing

is a remarkable method of enhancing the surface properties

of shafts, gears and other highly stressed machine

parts.

- Low carbon steel

of finished shapes are converted by carburizing into

a composite consisting of a high-carbon steel case

and low carbon steel core.

- When this composite

is quenched to martensite and tempered, the high hardness

and strength of the case microstructure, combined

with the favorable case compressive residual stress

developed by interaction between the case and core

during quenching, produce very high resistance to

wear, bending fatigue, and rolling-contact fatigue.

|

|

| Advantages

durferrit carburizing |

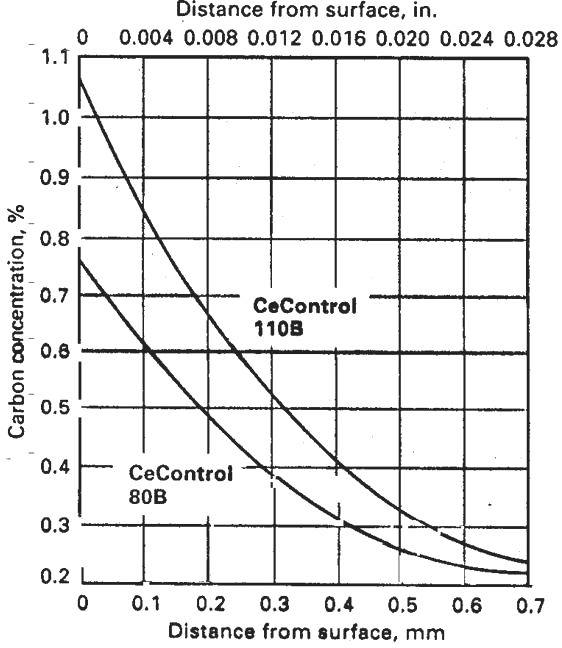

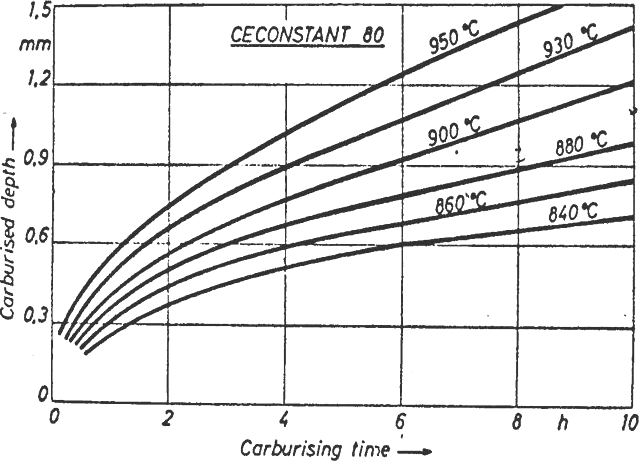

- CEconstant80

is the patent salt by Durferrit(Germany).

- Carbon potential

of salt can be easily controlled, thus carbon concentration

by carburizing can be easily obtained.

- Through carburizing

process, small amount of nitrogen is also induced

with carbon. (Carbo-nitride)

- Carbo-nitriding

be managed by treating temperature.

- Direct quenching

at carburize temperature will minimize distortion.

Economical and quick for even small amount production.

|

|

|

|

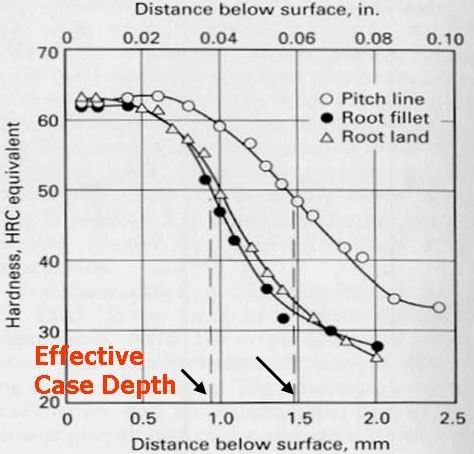

| Measurement

of

case depth |

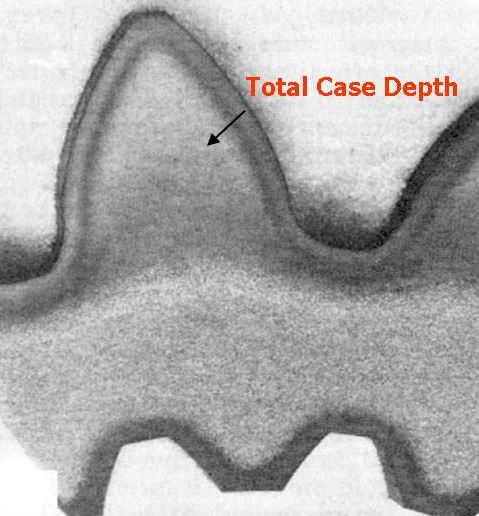

- Quality of carburized

part is usually specified by both surface

hardness and case depth.

- Case

depth is

defined as effective case depth

and total case depth.

It shall be clearly specified at order.

- 'Effective

case depth’

is a distance from surface to specified hardness,

if not specified, HRC50 is used.

- ‘Total

case depth’

is a distance from surface to the position where difference

between original matrix cannot be detected by any

of chemical etching or hardness check.

|

|

|

| Estimation

of CORE

HARDNESS |

The estimation of internal hardness of carburize part is available by using the jominy carve of the material. Select quenching media water or oil, select the portion of hardness required sush surface,

¾

from center or center, and then chose the actual diameter of round bar. The hardness can be estimated

at the crossing point of the ine draw down from a diameter and the jominy carve of the material. The surface hardness means uncarburized surface.

|

|

Top

|

|

|

|